Collaborative Robots: The Future of Safe and Efficient Manufacturing

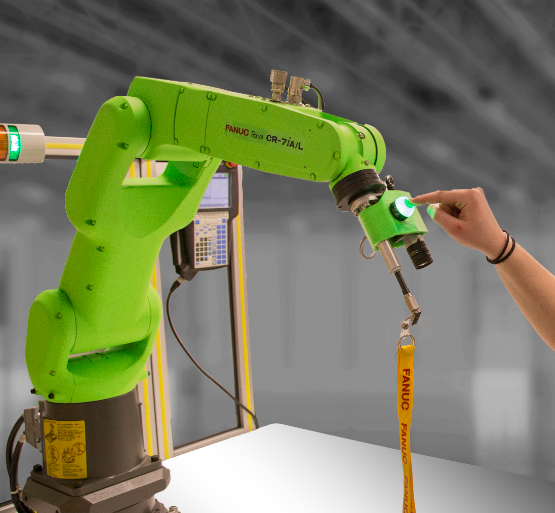

The manufacturing industry is on the cusp of a revolutionary transformation, driven by the emergence of collaborative robots, or “cobots.” These advanced robots are designed to work safely and efficiently alongside human workers, ushering in a new era of human-robot collaboration. Gone are the days of caged-off robots operating in isolation. Cobots are breaking down barriers, blurring the lines between human and machine capabilities, and reshaping the factory floor as we know it.

Veo Robotics: Pioneering Safe Human-Robot Interaction

At the forefront of this exciting evolution is Veo Robotics, a company dedicated to developing cutting-edge technology that enables safe and seamless human-robot interaction. Their innovative system transforms even the most powerful industrial robots into collaborative partners, mitigating safety risks and unlocking new possibilities for manufacturing processes.

How Veo’s Technology Works:

Veo’s system relies on a network of strategically positioned 3D sensors that constantly monitor the robot’s surroundings. These sensors generate real-time data, creating a dynamic 3D map of the workspace. Sophisticated software then analyzes this data to:

- Identify and track objects: The system accurately distinguishes between humans, machinery, and other objects within the workspace.

- Predict movement trajectories: By analyzing movement patterns, the software anticipates the future positions of objects, including humans.

- Control robot behavior: Based on real-time analysis, the system dynamically adjusts the robot’s speed and movement to maintain a safe distance from human workers.

Benefits of Collaborative Robots:

The integration of collaborative robots like those powered by Veo’s technology offers a multitude of benefits for manufacturers:

- Enhanced Safety: By eliminating the need for physical barriers, cobots create a safer work environment for human operators.

- Increased Efficiency: Cobots can handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex and value-adding activities.

- Improved Productivity: The seamless collaboration between humans and robots streamlines workflows, reduces downtime, and boosts overall productivity.

- Greater Flexibility: Cobots can be easily reprogrammed and redeployed for different tasks, providing manufacturers with greater agility and responsiveness to changing production demands.

Transforming Manufacturing: A New Era of Collaboration

The adoption of collaborative robots is poised to revolutionize the manufacturing landscape, enabling a paradigm shift towards more flexible, efficient, and human-centered production processes.

Bridging the Gap Between Human and Robot Capabilities:

Collaborative robots excel in tasks that require precision, strength, and endurance, while humans bring their unique cognitive skills, dexterity, and problem-solving abilities to the table. By combining these complementary strengths, manufacturers can optimize tasks and achieve levels of efficiency and quality that were previously unattainable.

Real-World Applications and Success Stories:

Collaborative robots are already making their mark across various industries:

- Automotive: Cobots assist in assembly lines, handling heavy components and performing intricate tasks alongside human workers.

- Electronics: Precision assembly of delicate electronic components benefits from the dexterity and accuracy of cobots.

- Logistics: Cobots streamline warehouse operations, assisting with picking, packing, and palletizing tasks.

The Impact of Collaborative Robots on the Future of Work

The rise of collaborative robots is transforming the nature of work in manufacturing, addressing safety concerns and creating new opportunities for skilled workers.

Addressing Safety Concerns in Industrial Settings:

One of the most significant advantages of cobots is their ability to enhance workplace safety. By working in close proximity to humans, cobots eliminate the need for bulky safety cages and reduce the risk of accidents caused by traditional industrial robots.

Creating New Job Opportunities and Enhancing Existing Roles:

Contrary to fears of widespread job displacement, collaborative robots are creating new opportunities for skilled workers. As robots take over repetitive tasks, human workers can transition to more engaging and higher-level roles that require creativity, problem-solving, and technical expertise.

Conclusion: Embracing the Potential of Collaborative Robots

The adoption of collaborative robots represents a significant leap forward for the manufacturing industry. By embracing this transformative technology, manufacturers can unlock new levels of safety, efficiency, and productivity, while creating a more fulfilling and future-proof work environment for their employees. As cobot technology continues to advance, we can expect to see even more innovative applications emerge, further blurring the lines between human and machine capabilities and shaping the future of manufacturing.

High Trust External URLs:

- Robotic Industries Association: https://www.robotics.org/

- International Federation of Robotics: https://ifr.org/

- National Institute of Standards and Technology (NIST): https://www.nist.gov/